Why Automotive Suppliers Audit Readiness Matters

Why Automotive Suppliers Audit Readiness Matters

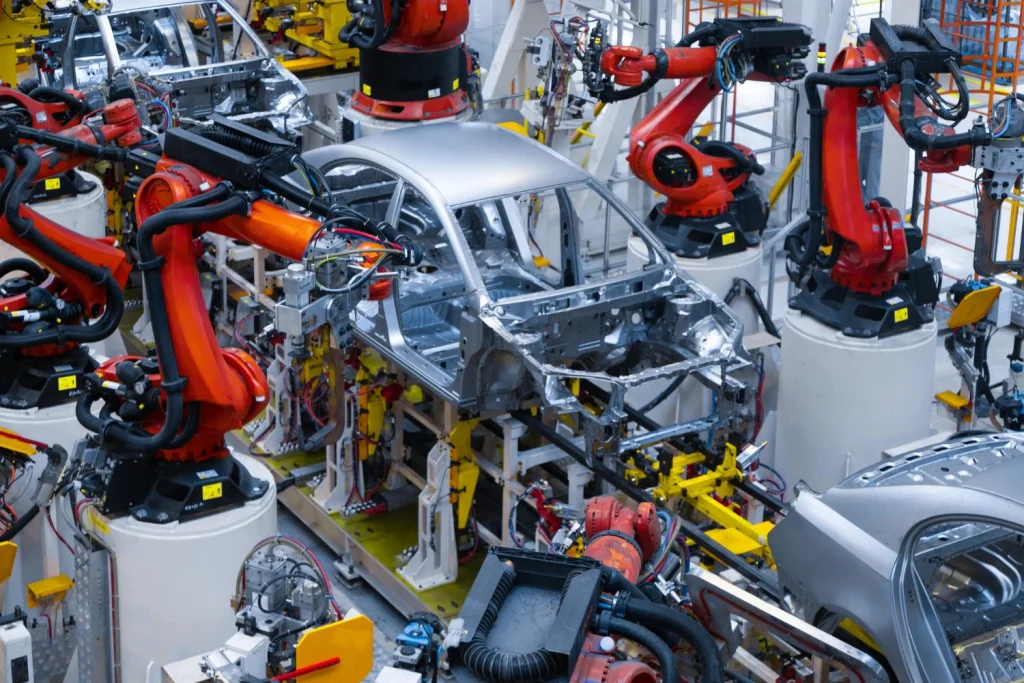

Kadmar Consultants helps providing services to Automotive Suppliers to stay competitive in the challenging era through a strong and effective Quality Management System. Want to do business with world-leading vehicle manufacturers like GM, Ford, Stellantis, Honda, and Toyota? IATF 16949 certification is no longer optional — it’s the entry ticket for doing business. Unfortunately, suppliers treat audits as an annual event — a paper requirement. You become what you think. Result? Panic before audits, last-minute documentation rushes, and increased risk of nonconformities. True leaders know that in this competitive era, operational excellence is the key to survival. In this blog, Kadmar Consultants helps Automotive Suppliers understand how to maintain continuous compliance and process maturity through effective Quality Management System implementation.

Understand What “Audit-Ready” Really Means

Audit readiness means your Quality Management System (QMS) works as intended — anytime. The organization achieves operational excellence, eliminates repeat issues, and strategically turns risks into opportunities. A truly audit-ready organization will have:

- Employees with high morale and proper training.

- Multi-skilled employees.

- Systems demonstrating compliance with IATF 16949 clauses through evidence.

- Processes achieving their intended purpose.

- Controlled records available on demand.

- Audit readiness = culture + system + evidence.

Embed Audit Readiness into Daily Operations

Successful automotive suppliers stay in audit mode all the time — not just to satisfy paperwork, but to run systems built on strong QMS frameworks that make them preferred OEM providers.

- Work instructions are living documents — update as needed.

- PFMEA-CP-WI should be integrated into the QMS along with CSRs.

- Conduct layered process audits (LPAs) weekly to catch small deviations early.

- Implement an effective Management Review Process to support continual improvement.

- Hold monthly touchpoints with all process owners.

Kadmar Insight:

“If you need to ‘get ready’ for an audit, your system isn’t fully implemented.”

Plan Internal Audits Strategically, Not Formally

Companies often treat internal audits as a requirement under Clause 9.2, but it is actually a strategic tool.

How to Optimize Internal Audits:

- Audit High-Risk Processes More Frequently

All processes need to be evaluated based on risk and audit frequency should be driven from risk assessment.

- Rotate Internal Auditors

Auditors can not audit their own process.

- Use Process Auditing Techniques

Process effectiveness and performance outcomes is the key deliverable to evaluate not just clause alone.

Kadmar Solution: We design and conduct second- and third-party internal audits aligned with IATF expectations to uncover risks before auditors do.

Automotive Suppliers Documentation Need

Document control is the key that shows if IATF is done strategically or is just serving a paper requirement. An IATF certificate can give you one time business but can not grow the business until you use IATF 16949 strategically as a tool to achieve competitive advantage. As it is said efficiency without effectiveness is nothing. Most common red flag in an audit is missing or outdated documentation.

Best Practices for Control:

- Develop and maintain a Master List of Controlled Documents with revision dates.

- Use version numbers on every form and procedure.

- Archive old versions properly to avoid confusion on the shop floor.

- Ensure records are retrievable within minutes, not hours.

Common Pitfall:

Many companies update documents but forget to train employees on new revisions — leading to nonconformities.

Pro Tip: Kadmar Consultants can help provide a system and training to work in effective and efficient way.

Strengthen Your Management Review Process

The most powerful tool in QMS is Management Review Process. It reflects how organization is performing.

Make It Effective:

- Use all required input as mentioned in IATF 16949 in Management Review Process.

- Customer satisfaction, performance trends, and risk updates is key to success.

- Use data visualization (dashboards, KPI charts) for decision-making.

- Record action items, owners, and deadlines.

- Review the effectiveness of previous actions each session.

Kadmar Advantage: Our consultants facilitate structured management review workshops that transform data into strategy and measurable improvement.

Build a Culture of Risk-Based Thinking

Clause 6.1 of IATF 16949 emphasizes to evaluate risks and opportunities for each process and define control to be in place to have an effective and competitive environment.

- Integrate Risk-Based Thinking Daily.

- Review risk for each process and define objectives and controls.

- Use FMEAs to define risk and control plans to define controls and procedure.

- Update risk levels after every significant change or customer complaint.

Example: If supplier delivery delays increase, review how that risk affects customer satisfaction and internal KPIs — then adjust contingency actions.

Kadmar Consultants Solution: We provides custom risk management matrices that tie IATF requirements to your actual operations.

Keep Supplier Network Audit-Ready

Stakeholders interest and their needs and expectation can shape organization’s ability in achieving or hindering its mission and vision. Work with your suppliers for their performance and audit readiness. Many IATF findings trace back to weak supplier controls.

Supplier Readiness Framework:

Review their performance (PPM, OTD, audit results) and conduct supplier development audits regularly. Define escalation paths for poor-performing suppliers.

Kadmar Service: We help clients establish supplier monitoring systems and vendor audit programs that align with IATF and OEM expectations.

Conduct Layered Process Audits (LPAs)

Layered Process Audits is the effort of unwinding small process deviations before they turn into nonconformities.

Effective LPA Implementation:

Management commitment and leadership involvement is the key of effective LPA implementation. Define daily, weekly, and monthly audit layers and keep audits short (10–15 minutes). Trend recurring findings and take preventive action.

Kadmar Consultants Solution: Offers LPA design and rollout services that build accountability and strengthen operational discipline.

Leverage Continuous Improvement

Continuous system monitoring and finding opportunities for improvement and drive continual improvement project through gaps in the processes. Customer complaints and warranty claims is opportunity for improvement for future events.

Scrap and rework trends are used to eliminate repeat issue.

Example: A consistent rise in internal scrap may indicate a weak control plan or ineffective operator training — both red flags during audits.

Prepare Your People — Not Just Your Paperwork

Happy customer reflects happy employee and healthy environment.

The people are part of system and should be engaged and valued.

Auditors often ask operators and engineers direct questions to assess process ownership.

Train employees on their process responsibilities.

Post QMS policy everywhere, it is not about memorizing it but understanding the intend and what it means to the

Remember: Competent, confident employees are your best evidence of system effectiveness.

Kadmar offers: Audit Readiness Training Workshops that simulate real IATF audit scenarios.

How Kadmar Consultants Helps

Kadmar Consultants specialize in simplifying certification. Our experts provide:

- IATF 16949 and ISO 9001:2015 Implementation Services.

- Documentation support.

- Gap analysis and process mapping.

- Internal audit services.

- IATF 16949 Understanding and Internal Auditor Training.

- ISO 9001:2015 Understanding and Internal Auditor Training.

- Problem Solving and 8D Training.

- Audit readiness coaching.

Take the First Step Today

If you’re preparing for IATF 16949 certification, don’t go in blind. We build businesses and help them grow. We make sure Quality Management System is embedded in the organization that helps operational excellence. IATF 16949 and ISO 9001:2015 is not just a paper document but a living standard.